Cynora, established in 2003 in Germany, was a developer of materials for OLEDs and OPVs. Cynora started out to develop copper-based OLED compounds, in addition to developing flexible OLED and OPV technologies.

Cynora, established in 2003 in Germany, was a developer of materials for OLEDs and OPVs. Cynora started out to develop copper-based OLED compounds, in addition to developing flexible OLED and OPV technologies.

The company later changed direction and focused on TADF OLED emitters, specifically aiming to develop an efficient blue emitter. The company hoped to have a commercial blue by 2017, but it was not successful.

In 2020 Cynora announced its first commercial product, a fluorescent blue emitter that is 15% more efficient that current fluorescent blue emitters on the market. Cynora branded its new material as cyBlueBooster. We are not aware of any companies that actually adopted this new material. In March 2020 we posted an interview with Cynora's CEO to discuss this new material.

In 2021, Cynora announced that it achieved a breakthrough in its deep-green TADF material, which it brands as cyUltimateGreen. Cynora started to offer test kits of the new deep-green emitter and Cynora promised it will follow soon with a deep-blue TADF solution. The company did not provide any updates since.

In June 2022 Samsung Display acquired Cynora.

Werner-von-Siemens-Strasse 2-6 Building 5110

76646 Bruchsal

Germany

Samsung Display acquires TADF material developer Cynora

According to reports, Samsung Display acquired OLED material developer Cynora, for about $300 million. Samsung acquires just the IP and technology, and Cynora terminated its entire workforce a couple of weeks ago. Samsung is already an investor in Cynora, and so is LGD.

Cynora has been low on cash (its last financing round was in 2019), according to reports, and did not manage to find new investors, and so the company opted to be sold to Samsung. The reported sum seems to be rather high for an emergency exit, and some later reports quotes much lower sums, perhaps even around $30 million or so.

How machine learning and AI help find next-generation OLED materials

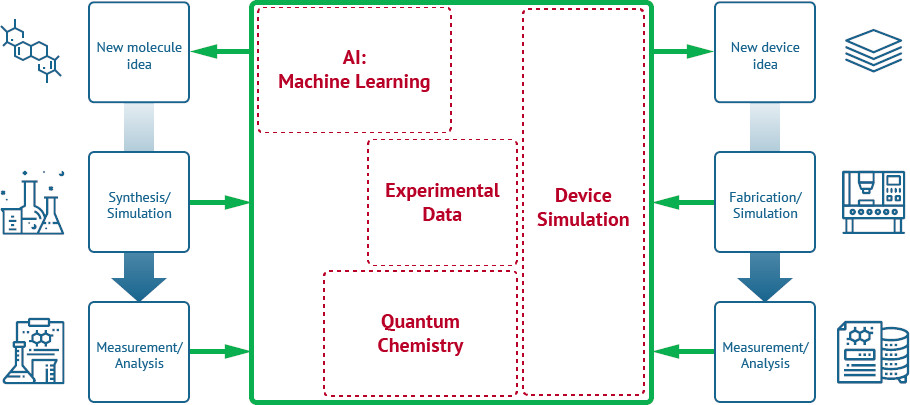

In recent years, we have seen accelerated OLED materials development, aided by software tools based on machine learning and Artificial Intelligence. This is an excellent development which contributes to the continued improvement in OLED efficiency, brightness and lifetime.

Kyulux's Kyumatic AI material discover system

The promise of these new technologies is the ability to screen millions of possible molecules and systems quickly and efficiently. Materials scientists can then take the most promising candidates and perform real synthesis and experiments to confirm the operation in actual OLED devices.

Cynora achieves breakthrough in its green TADF material, test kits are now available for display makers

OLED material developer Cynora announced that it achieved a breakthrough in its deep-green TADF material, which it brands as cyUltimateGreen. The new material delivers an efficiency of over 20% (EQE), a lifetime of 400 hours (LT95@15mA) and a color point and emission spectrum that matches today's DICI-P3 standard (Cynora does not specify the exact number).

Cynora further announced that is now making test kits of the new deep-green emitter available to its customers. Display makers can now start testing and verification using the new material. Cynora says it will also 'soon' follow with a deep-blue TADF solution.

A Q&A with Cynora's CEO, to discuss the company's new blue emitter

OLED material developer Cynora recently announced its first commercial product, the cyBlueBooster fluorescent blue emitter that is 15% more efficient that current fluorescent blue emitters on the market.

This was a very interesting announcement, and Cynora's CEO Adam Kablanian was kind enough to answer a few questions we had to help understand the new material and Cynora's current business and latest technology.

Cynora announces a new blue fluorescent emitter that is 15% more efficient than current emitters

OLED material developer Cynora announced its first commercial product, a fluorescent blue emitter that is based on an "advanced molecular design" that is 15% more efficient that current fluorescent blue emitters on the market. Cynora brands its new material as cyBlueBooster, and it says it is currently available for commercialization in several shades of blue.

This could be very exciting news - while the whole industry is looking for next-generation emitters using TADF or PHOLED technologies, Cynora could have found an easier path to reduce power consumption by 15%. OF course a TADF or PHOLED emitter will achieve a reduction of 75% in power consumption compared to currently-used fluorescent emitters.

TADF OLED emitter technology - industry status

TADF, or Thermally Activated Delayed Fluorescence, is a relatively new class of OLED emitter materials that promise efficient and long-lifetime performance without any heavy metals. TADF research started at around 2012, originally at Kyushu University in Japan and today many academic groups and several commercial companies are developing TADF materials.

The main reason companies are interested in TADF emission is that it could lead to an efficient and long-lasting blue OLED emitter - something that hasn't been yet achieved by other means (mainly - UDC's Phosphorescent OLED emitter technology). In recent years companies initiated commercial development of red, green and yellow TADF emitters as these can offer a lower cost alternative to UDC's PHOLEDs materials.

Cynora raised $25 million in its Series C funding round

TADF developer CYNORA announced that it has secured $25 million in its Series C funding round from investors in Asia, Europe and the US. Since 2008, Cynora raised $80 million.

Cynora's latest deep-blue material specification was presented in May 2018 - with a CIEy of 0.14, EQE of 20% and a lifetime of 20 hours LT97 at 700 nits. Cynora expects to have blue material in mass production by 2020. In October 2018 Cynora extended its joint-development agreement with LG Display.

Things we learned at the first day of OLED Korea 2019

The first day of the OLED Korea 2019 conference is almost over - with some interesting lectures and talks by leading OLED companies and professionals. Here are some of the things under discussion today (highlights only):

- Some believe there will be a real market for >$2,000 foldable OLED devices, and some call for cost reductions before real adoption could take place

- LG Display is optimistic regarding the future of OLED TVs

- Samsung will not commit yet to its QD-OLED technology

- Both Cynora and Kyulux are rapidly progressing towards a long lasting TADF/HF blue - but it seems there's still work to be done

- Idemitsu Kosan is increasing its fluorescent OLED emitter efficiency

- Universal Display's RGBB architecture is back on the table - and the company now highlights the architecture's low blue light emission. UDC seems more optimistic then ever regarding blue PHOLED commercialization

- Equipment maker's focus is shifting to China as Korean OLED makers will not increase capacity in the near future

Cynora extends its cooperation with LGD for deep-blue TADF emitters, samples green TADF emitters

TADF developer CYNORA has announced that it has extended its joint-development agreement with LG Display. The two companies have been co-developing deep-blue TADF OLED emitters for two years, and have now decided to continue the cooperation towards the commercialization of TADF emitters in OLED displays.

CYNORA's latest deep-blue material specification was presented in May 2018 - with a CIEy of 0.14, EQE of 20% and a lifetime of 20 hours LT97 at 700 nits. Cynora expects to have blue material in mass production by 2020. Cynora says that its TADF materials are suitable for both self-emitting or co-emitting approaches (which includes hyper-fluorescence).

Cynora to present its latest blue TADF emitter at the OLEDs World Summit conference

TADF developer CYNORA announced that it will present its latest deep-blue TADF emitter material at the OLEDs World Summit which starts today in San Francisco.

CYNORA's latest material specification was presented in May 2018 - with a CIEy of 0.14, EQE of 20% and a lifetime of 20 hours LT97 at 700 nits. Cynora expects to have blue material in mass production by 2020, and when its deep-blue material is ready it will start to develop the less challenging highly efficient green and red materials. Last month we interviewed Cynora's CMO Dr. Andreas Haldi - who talked about TADF, lifetime, color points and more.

Pagination

- Page 1

- Next page